The project consists of developing commercial solutions that allow commercial vehicle owners to transform their engines into compressed air.

Addressing GHG emissions from transportation requires replacing fuels. The only effective alternative is electrification, which imposes the use of batteries, which have been in development for more than a century and remain a technology that is burdensome in terms of cost, constraints and environmental impact. Compressed air makes it possible to recover existing engines, uses simple technological solutions, has little environmental impact, air tanks allow an unlimited number of charge and discharge cycles, GHGs are eliminated more than 95% .

Use of compressed air as an energy vector.

Use of compressed air as an energy vector

Anthos Air Power Normandie develops retrofit kits for the goods and passenger transport market (Pickup, Van, minibus) making it possible to convert any engine into an engine using only compressed air or nitrogen as a vehicle for energy.

Anthos will initially offer to professionals using internal combustion vehicles to transform them to replace fuels with compressed air in order to completely eliminate GHG emissions, electrify transport and allow them significant savings in their costs. transaction costs.

In a second time, Anthos will promote the use of compressed air in all forms of transport.

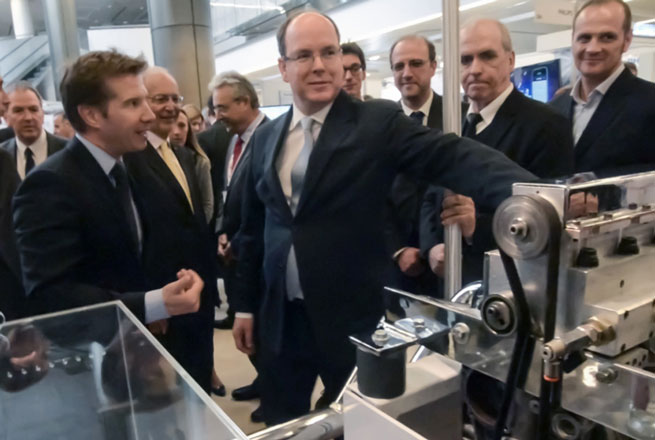

The first vehicle was presented in April 2019

The first vehicle to receive an Air Power kit retrofit will be a 3.5 tonne utility vehicle.

Its autonomy in town will be 200km with a useful load of 10M3

The first vehicle was presented on April 04, 2019 in Rouen.

An Air Power utility vehicle running 45,000 km a year in the city will avoid the emission of 13 tonnes of CO2 by emitting no particles in the air. In addition, it will filter more than 200,000 M3 of ambient air.

Its equipment has a lifespan of at least 15 years it has a very small footprint on the environment even over its entire life cycle when electric vehicles have left over this period nearly 2 tons of metals in nature.

Breakdown by source of GHG emissions (excluding UTCF) in France in 2015

Source : Citepa, 2017

Environmental impacts

- The technology allows the elimination > 95% of GHGs on this segment (small trucks, commercial vehicles, buses),

- It allows the elimination of all the pollutants produced by the combustion of fuels,

- The manufacture of aluminum parts of modification kits is a conventional machining that does not require a chemical input and low energy intensity,

- The modification of the vehicles requires only workshops of conventional mechanics without heavy tools, no chemical input or high energy expenditure,

- The parts eliminated, fuel tank, pipes, engine parts are recycled according to the standards in force,

- The lifespan of vehicles to be extended significantly, the consumption of materials, metals, plastics should decrease overall,

- The compressed air engine produces cold, it allows to consider the elimination of GHGs and pollutants from refrigerated trucks without endangering the cold chains.