Air Power EngineAIR POWER

High efficiency compressed air

Air power has developed the first high-efficiency compressed air motor thanks to an international patent that increases the yields known to date by four times.

The use of compressed air alone as a means of propulsion allows a great flexibility and various applications, in different highly ecological fields. Through a conversion kit, air propulsion can be applied to existing engines or systems.

It also serves as a substitute for diesel and is a storage solution for renewable energies: Anthos offers the first and only alternative storage solution to batteries with the advantage of having infinite charging cycles and a lack of pollution by heavy metals, with a very economical solution and easy to put into operation.

The main renewable energies, solar and wind, are intermittent and unpredictable, vary with the seasons and are rarely in line with demand. Energy storage is therefore a key technical issue for the future development of clean energies.

Batteries are the only viable solution currently. Despite all the progress made over the last two decades, they remain expensive, have a limited life of 1000 or 2000 cycles of charges and discharges and are of a real complexity in terms of recycling.

Compressed air is therefore an advantageous solution: economical, clean, unlimited in cycle, technologically simple, and very attractive for sites far from power grids seeking to build a reliable and long-term energy solution.

- ENERGY STORAGE :

By combining the fluid-dynamic properties of air and the efficiency of the compressed air motor, electrical energy can be stored in the form of compressed air. We can thus reuse compressed air on demand to supply the cold chain, users and produce energy via an alternator.

The injection of electrical energy into the network can be programmed and distributed later, contributing to the quality and safety of the electrical system. These solutions can be used for “power” or “energy” services.

- GOVERNMENT ORIENTATIONS :

Governments have defined strategic lines to guide investments, subsidies and subsidies that it offers: fight against greenhouse gases (GHGs), emission market, electrification of transport, Plan Nord, development of remote sites, development of the sustainable economy and the circular economy.

Our solution will therefore be very important in the coming years as energy storage is one of the key points of the circular economy and one of the strategic orientations of the government.

The test phases have shown excellent results and our solution will soon be marketable.

The particularity of the Airpower engine is the presence of anti-vacuum valves that reduce losses during expansion. Indeed, these valves allow the ambient air to enter the cylinder when the pressure inside the piston is equal to or less than that of the atmosphere, this allows us to inject the bare minimum of air into the cylinder:

- No CO2 production;

- Allows the use of different renewable energies efficiently;

- Modular and adaptable system;

- Cold production that can be valorised.

- Generation of cold:

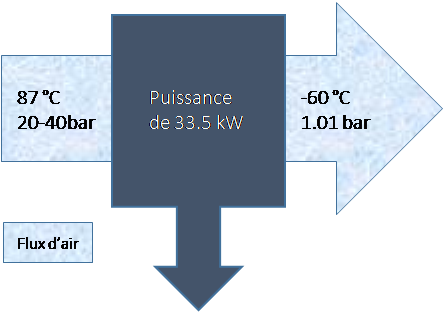

The air comes out of the engine at a temperature of -60 ° C, so this cold air can be used to refrigerate premises or in production machineries

- Heat recovery:

The higher the inlet air temperature is the higher the efficiency of the engine will be. Many industrial processes create losses that can be used to produce more energy with this engine.

- Air storage systems :

As shown in the figure below the air enters the cylinder with a maximum inlet pressure of 40 bar We can store air from 50 to 400 bar depending on the volume available. There are already several certified systems for these pressures.

The engine can be used in place of a heat engine in a personal vehicle or a bus. The technology developed by Airpower allows retro-fit.

To allow enough energy to be shipped to have a range of 200km you need 1m3 of air at 400 bar or …. in liquid form. The air will then pass through a cycle that will bring it into the cylinders at the desired pressure and temperature. In the following diagram we have shown the operation of a vehicle running on a 1m3 tank at 400 bar.

- Marine

- Agriculture

- Mines

- Forestry

- Construction

- Data and telecommunications centers

- Events

- Municipalities

- Airports

- Hospitals, clinics and emergency services

- Water treatment plants

- Off-grid / Isolated places

- Emergency groups of collective buildings …